Dassault launched its new Falcon 7X mid of February 2005. This plane – really beautiful – is a very important milestone in the virtualization of the concept, prototyping, tests, model and production of the Dassault’s airplanes. A very good example to my mind, how a piece of software can totally change the way an industry is working.

For the first time with the Falcon 7X, Dassault could save the required investment due to the first three prototypes which are normally used as validation and test platforms. The three first Falcon 7X will be simply….sold!

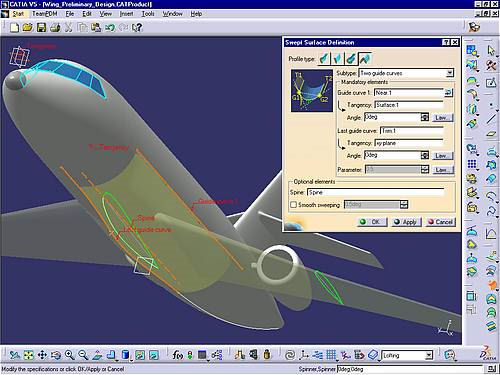

This fast complete virtualization of the conceptual process is based on a software developped by Dassault – Catia. Catia was developped at the beginning of the 70’s by Dassault Systems as a simulation tool. All airplane producers are using Catia, including Boeing and Airbus. 65’000 clients of Catia around the world in 80 different countries. With the last version of Catia, the engineers have the possibility to work directly with the numerical models thanks to 3D-glasses, at a 1:1 scale! This allows for example to check if all the technical elements are accessible easily by the technicians during the maintenance phases…. You can imagine the kind of optimization you can bring in the field of repairing processes. Impressive.

How complexe is it to produce an airplane as the Falcon 7X?

– 27 different companies are integrated and associated to the production process

– the conceptual phase required 18 months, with about 400 engineers from 7 different countries

– they all used Catia (with a central database called Enovia) to work on the concept

– the airplane is made of 40’000 elements, 200’000 fasteners and….25 kilometers of cables

Dassault Systems, with Catia and Enovia, defines a complete Product Lifecycle Management system for:

– the conception of the plane

– the definition of all the technical elements in detail

– the definition of the production industrial process with all the integrated partners

– the management of the final “put-all-these-things-together”

– the definition of the maintenances for the coming….30 years.

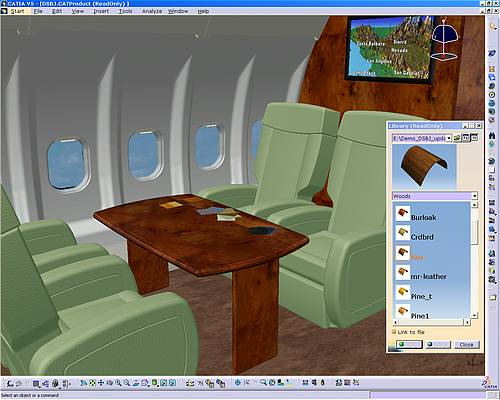

The numerical model is also used in the selling process. The potential client has an acces to the virtual plane, can choose the color and leather of the seats, the type of crockery and toilets, etc.

Great example of a piece of software which is changing the complete production and conceptual process of an industry.